Wastewater Reuse for Community Irrigation: The City of Key Colony Beach, Florida

The Challenge

In 2013 the City of Key Colony Beach sought to replace their existing reverse osmosis treatment plant and equipment which had reached the end of its useful life. The application presented a series of unique challenges most notable the source water: secondary clarifier effluent, from the onsite wastewater treatment plant, influenced by tidal infiltration resulting in TDS swings from 2,000 to 16,000 mg/L.

The Solution

In March of 2013 Harn R/O competitively bid and was awarded the contract to supply the replacement equipment; a single 7:0 ‐ 4 element train designed for 45% recovery.

The Result

A high efficiency system designed for maximum energy recovery through wide swings in feed TDS and temperature that produces less than 50 TDS permeate. Major points of emphasis within the design included a custom fiberglass frame complete with 316 stainless steel hardware to combat the corrosive environment of this application and the Florida Keys, use of an energy recovery turbo designed for maximum energy recovery and transfer of concentrate energy to the feed water.

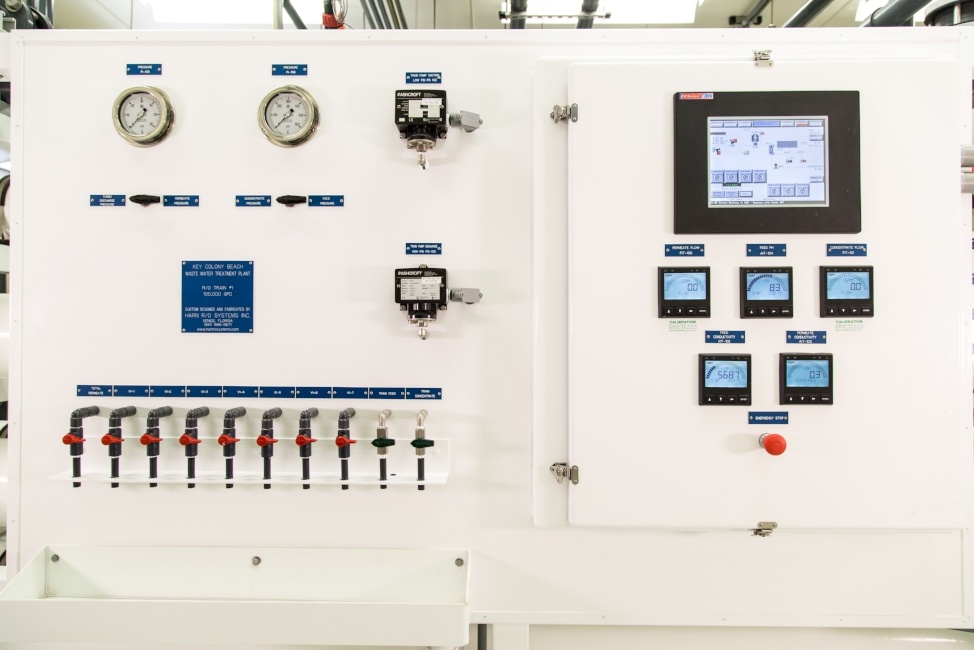

Harn R/O was responsible for providing the RO system, cartridge filtration, RO high pressure feed pumps, energy recovery turbo, controls, scale inhibitor pretreatment system, and cleaning system. Harn was also charged with onsite equipment installation, performance testing, training, and system performance monitoring.

Brief R/O System Specification

| Owner: | The City of Key Colony Beach, Florida |

| Application: | Treating wastewater for use as an irrigation supply |

| Startup: | December 2014 |

| Capacity: | 100,000 gallons per day of permeate water at 45% recovery |

| Array: | Single stage, 7 pressure vessels containing 4 elements per vessel |

| Pretreatment: | Scale inhibitor, cartridge filter |

| Low Pressure Piping: | Sch. 80 PVC |

| High Pressure Piping: | 316 Stainless Steel |

| Membrane Type: | Hydranautics SWC5‐LD |

| Frame Material: | Fiberglass reinforced polymer (pultruded) |

Operating Data |

|

|---|---|

| Feed Conductivity: | 6,680 μS/cm (at start‐up) |

| Feed Temperature: | 28.2 °C |

| Feed Pressure: | 210 psig |

| Turbo Boost: | 42 psig |

| SDI: | 1.25 |

| Permeate Conductivity: | 25.5 μS/cm (99.6% rejection) |

| Permeate Flow: | 70.2 gpm (45% recovery) |

| System Features: |

|